A Quilt for under $100? Really?

Don't Let This Happen to You!

Your Parents Were Right! You Get What You Pay For!

I totally understand budgets and costs. We all have budgets and have to live within them or make trade-offs. So if cost is the most important factor, then there are some expectations you should have with letting cost drive your decision.

What to Expect From a $74.99 “Quilt”

As a child we were taught an important life lesson – you get what you pay for. Nowhere is that saying truer than when it applies to quilts.

Here is what you can expect from a $74.99 so-called “quilt”...

1.Your graphics will be cut off.

This is a given. The standard industry square size is either 12” or 14”. If you’re graphics are larger than those two sizes, they’ll be cut and many times cut off center. The die machines they use don’t allow for the operator to see where the cut lines will go. Many times, two or three, are cut at a time. They have to. For the price, they have to cut as many as possible as quickly as possible.

Here at Meg’s, we do two styles of quilts. The mosaic will guarantee that your graphics will never be cut. We also do the checkerboard style and use a 14” square. This fits most shirt graphics. However, if any graphic will be compromised in the cutting process on the checkerboard, we will take pictures and send them to you for review and approval before we cut. This way you know where the cuts will take place. You’ll also have the opportunity to switch to the mosaic, if you’re not comfortable with cutting the graphics.

2.You’re getting a blanket, not a quilt.

I put the word “quilt” in quotations when referring to what you get for $74.99 simply to set it apart from the actual meaning of the word quilt. Sewing squares together in a row does not make a quilt. What those companies are actually making are blankets but they’re advertising them as quilts, which is deceiving -- they know it and think that you don’t.

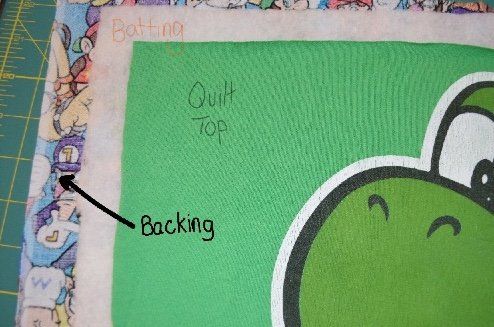

Think of sandwich cookies and potato chips. A quilt is like a sandwich cookie! It has three layers. For a quilt, you have your shirts (top), the middle (batting) and the backing. The three layers are held together with stitching or quilting. The quilting is important for keeping the three layers together as well as to stabilize your shirts. They will not continue to sag and stretch with use and wash.

Blankets are like a bag of potato chips. There are only two layers. You can pull the front and back apart like you’re opening a bag of chips. This means your shirts aren’t stabilized. That’s what gives the saggy look to blankets and ensures that they don’t lay flat and can never be smoothed out. Once you move one area, it wrinkles another. Here are some examples:

Blankets are less expensive than quilts for a few reasons:

Skill

A blanket doesn’t require a high skill level. If you can teach someone to put shirt next to shirt and sew in a straight line, you can make a blanket. T-shirt blankets are taught in high school sewing classes.

Machinery

A blanket maker needs only a sewing machine. A t-shirt quilter needs a long arm quilter to complete the quilt. A long arm quilter can cost between $10,000 and $35,000. View our quilting video here:

Materials

Typically, blankets are backed with a fleece which is an inexpensive fabric. You can pick that up at JoAnn Fabrics for $4.99/yard retail, the wholesale cost will be significantly less. An experienced t-shirt quilter knows that an inexpensive backing can ruin a quilt. In addition to the batting and the specialized long arm thread, there is the backing fabric. High quality 100% cottons are best and many experienced quilters will purchase the same fabrics from the same manufacturers that you will find in quilt shops (not JoAnn’s).

Time

A blanket takes less time because there are two steps. It’s a production line. A stack of shirts are placed in front of a sewer. A 12 shirt blanket can be made start to finish in well under an hour. A 12-shirt quilt, here at Meg’s, takes 6 steps and about 4 hours to complete.

Workmanship

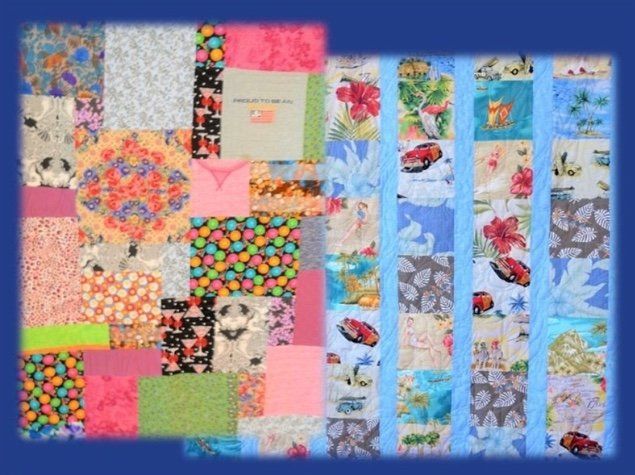

Due to the nature of the blanket making process, workmanship can be compromised. Blanket production lines have to work quickly and move as many through as possible, so if corners don’t match up, they don’t have the time to go back and fix it. The mistake is left in. If there’s a stack of shirts and three white shirts or three red shirts happen to be placed on top of each other, they are sewn together with no thought for the look or the design.

Meg's = Real Quilts, Real Quality!

Here at Meg’s, we are very thoughtful on the design and will move shirts around to separate colors when possible. In addition, we send you a picture of the layout before we sew anything. Sometimes, we rearrange a layout 3 or 4 times before a picture is sent to you for approval.

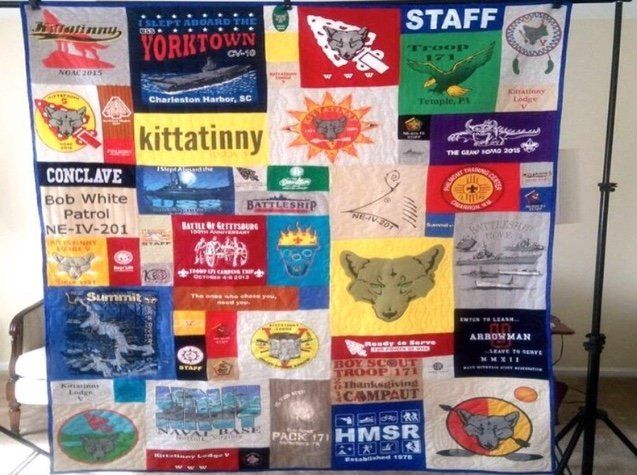

Compare the photos above to the high-quality craftsmanship you can count on from us:

Final Thoughts

You’ve been saving your shirts for a while or you’ve been collecting those shirts as your child grows, knowing that you want a quilt made that you’re going to love. There are many factors to consider – quality, style, workmanship and cost.

When looking at a quilt and comparing it to a blanket, remember that you are not comparing apples to apples. It’s more like comparing a fast food burger to a specialty bar burger. Both are food, but one costs more because of the superior quality of the ingredients and the time it takes to make it properly.

I would love to talk with you further about how our process works. If you have any questions, please reach out to me at meg@megsquiltedmemories.com!